建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

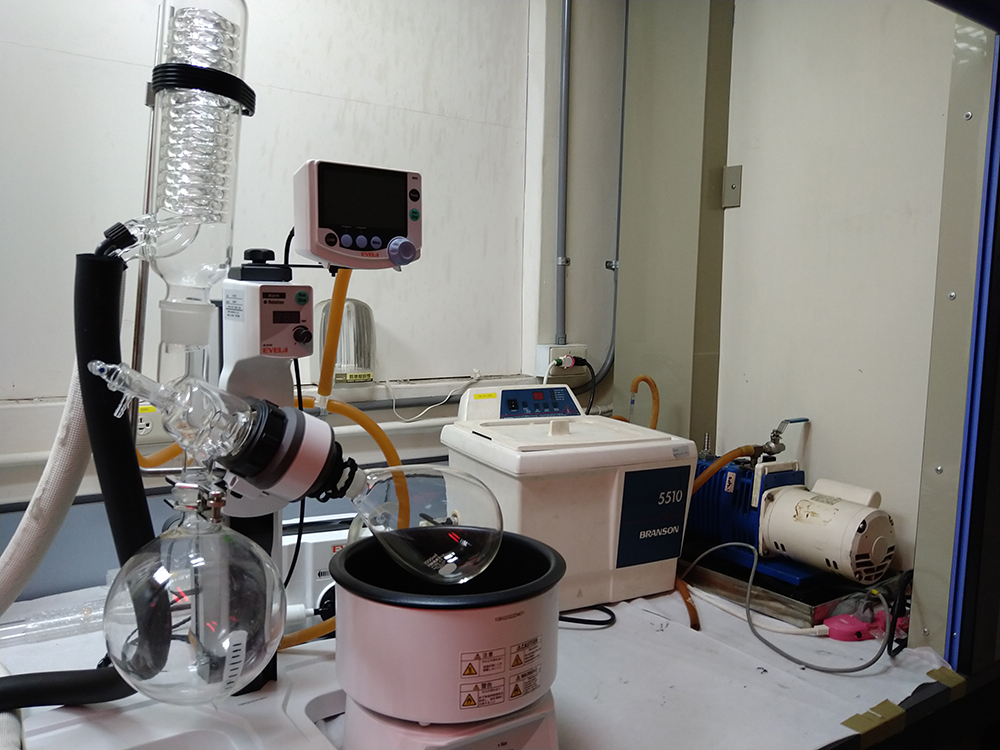

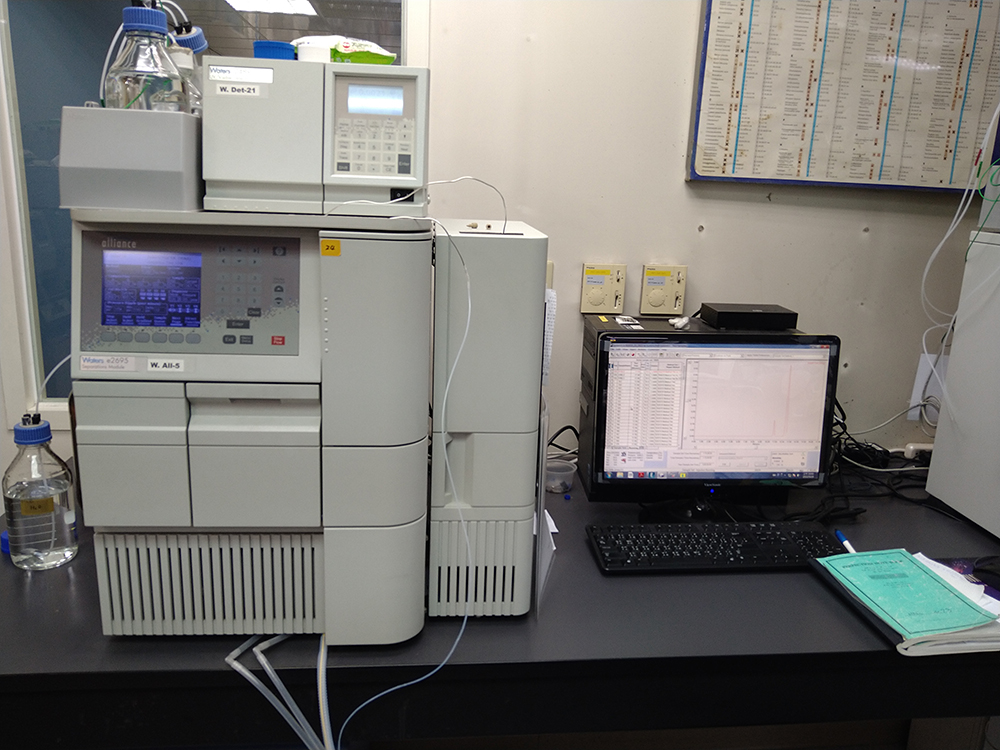

Panlabs utilizes a wide range of advanced purification technologies to ensure optimal product recovery and purity, offering scalable purification recovery solutions for production, including:

We provide single-operation technologies, including but not limited to extraction, concentration, resin adsorption, and desorption, purification, and crystallization, among others. We also integrate multiple technologies to create highly efficient purification and recovery processes. Our team is dedicated to transforming small-scale processes into industrial-scale production. We ensure high recovery rates and consistent quality, thereby helping our customers improve production efficiency and market competitiveness.

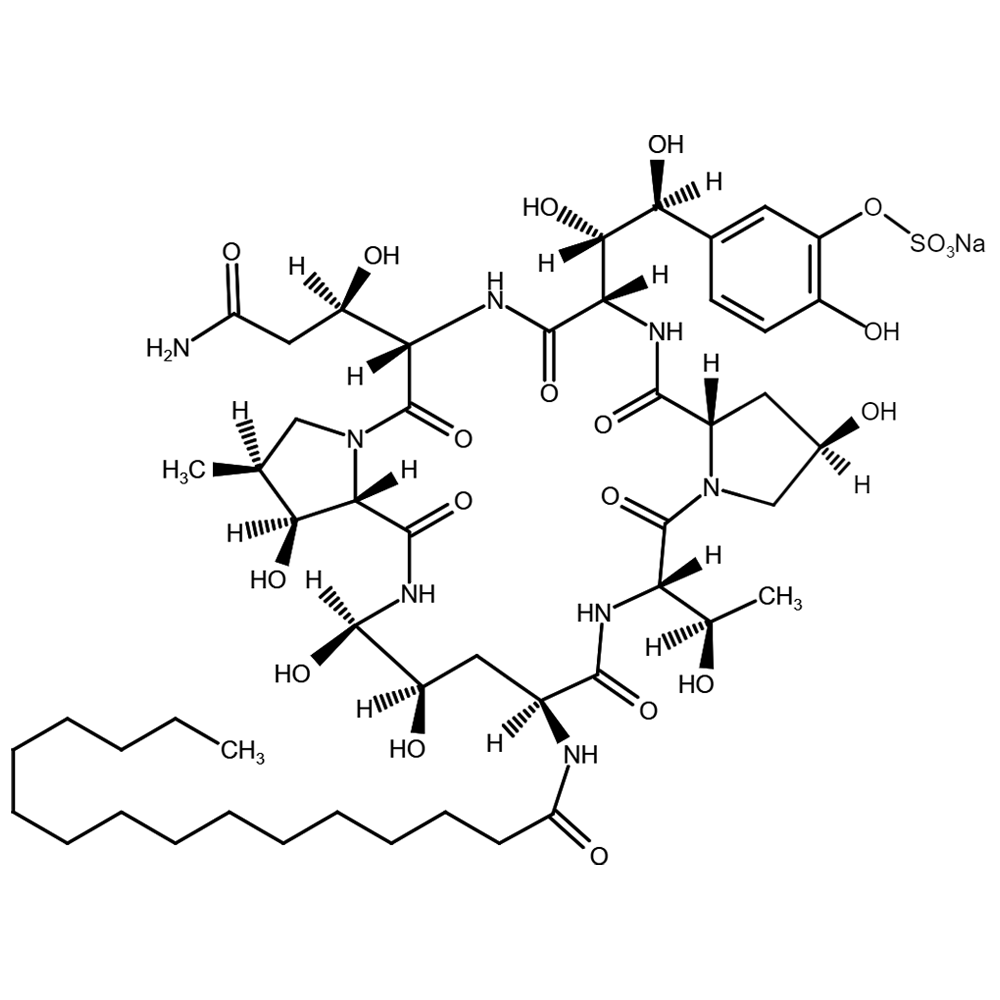

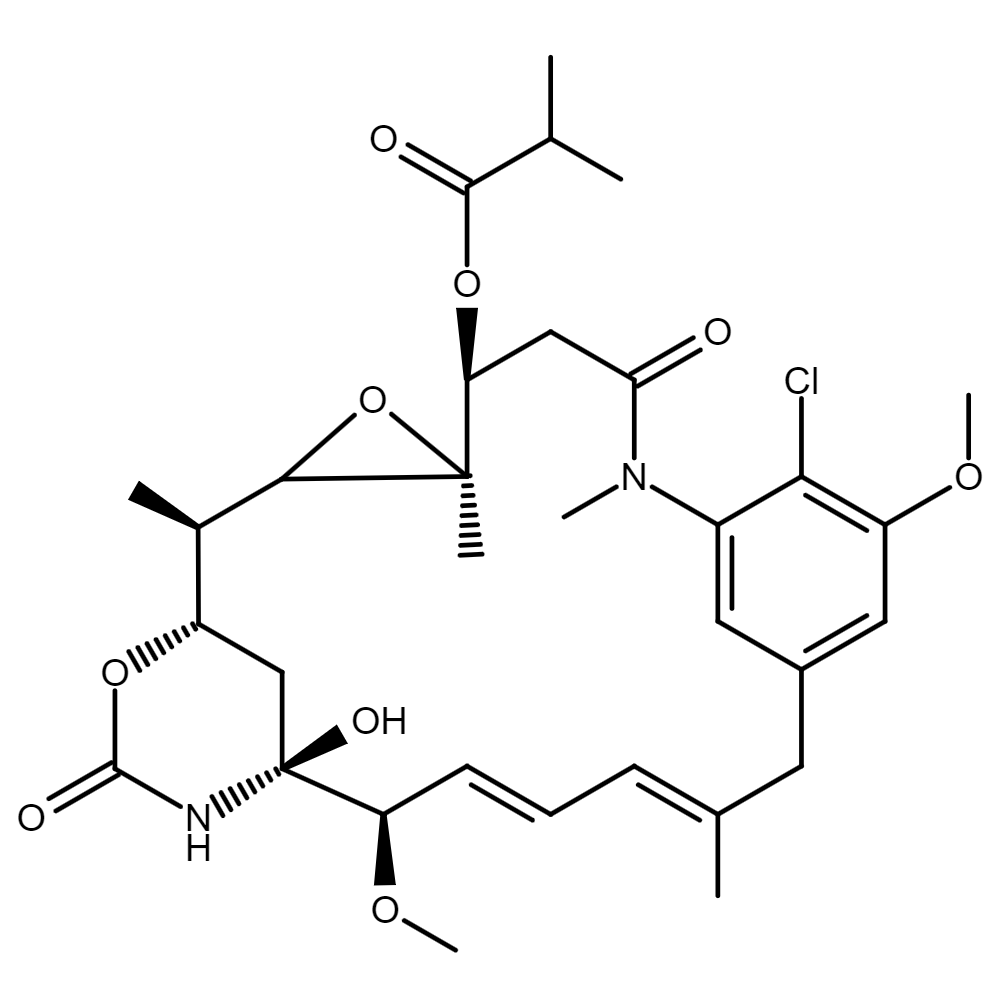

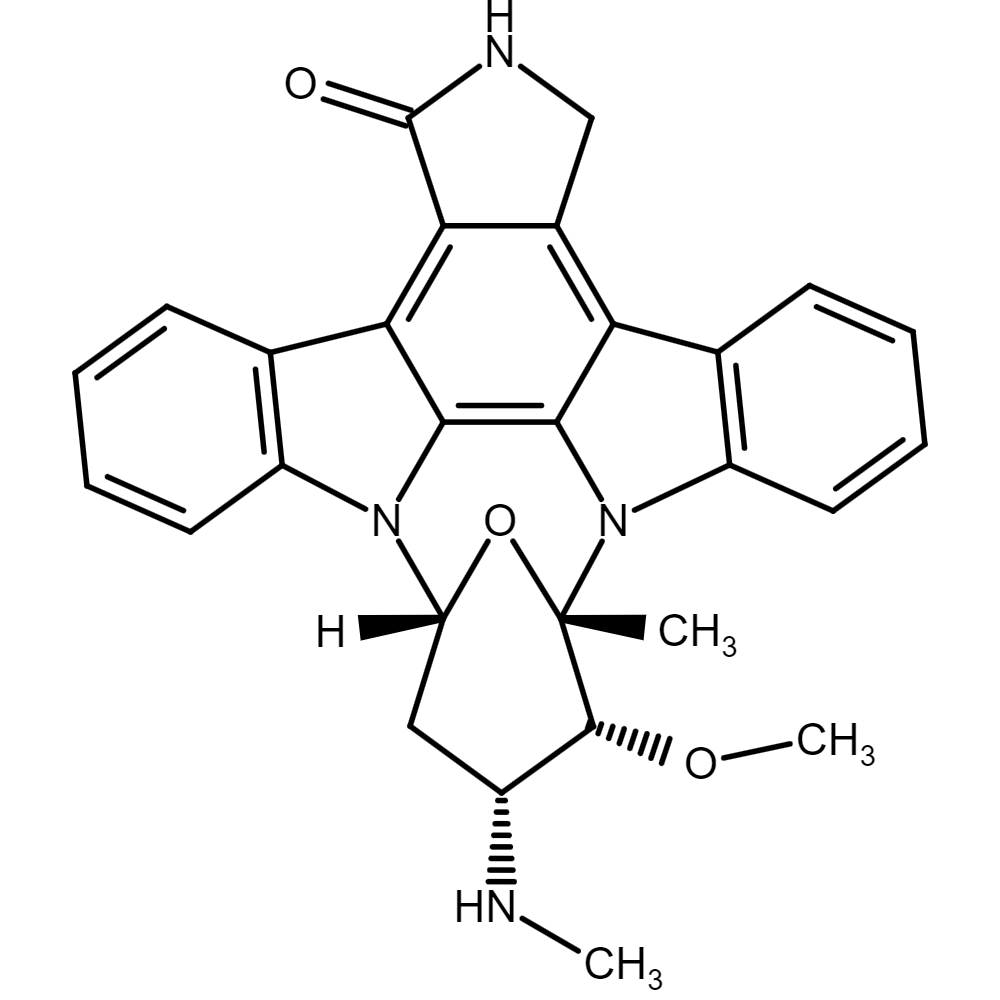

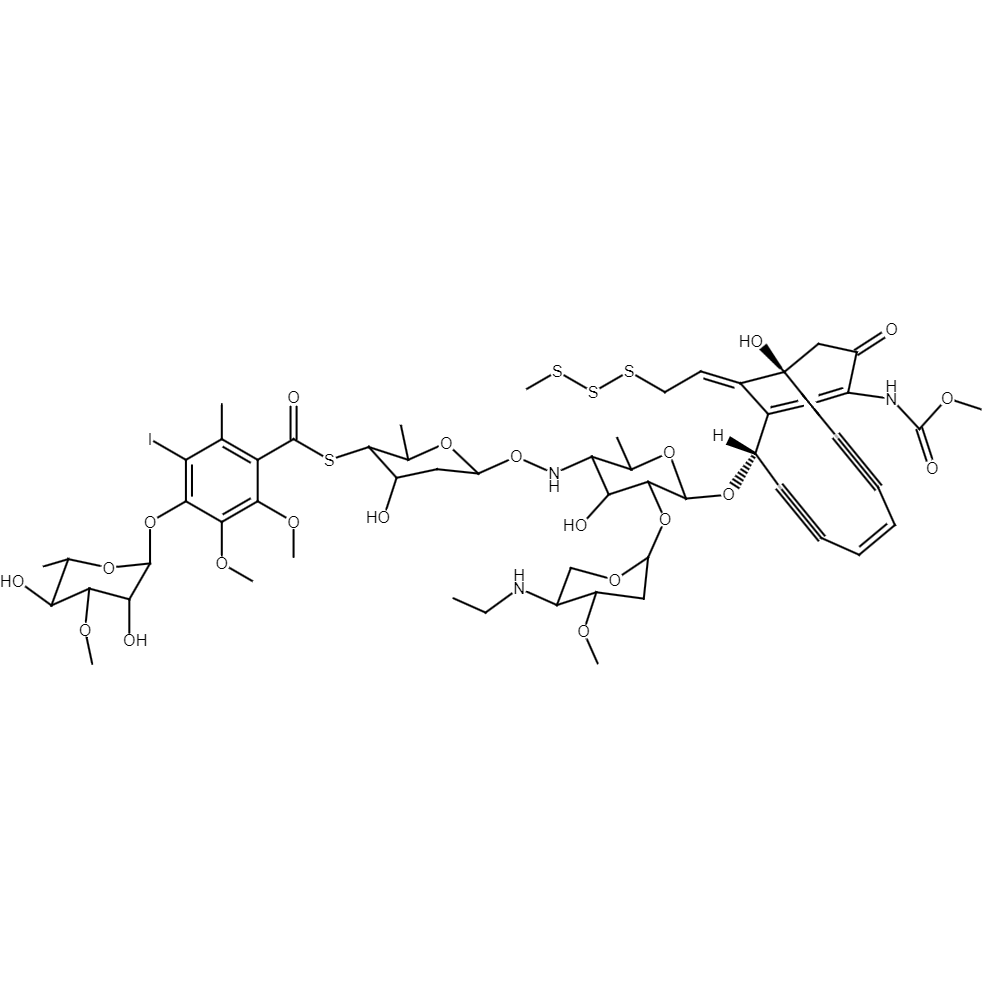

FR901379 (Micafungin intermediate; CAS: 144371-88-0), Ansamitocin P-3 (AP3; CAS: 66584-72-3), Staurosporine (CAS: 62996-74-1), Calicheamicin γ1 (CAS. 108212-75-5), Calicheamicin γ1 (CAS: 108212-75-5), etc. are also our successful cases.