建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

With over 50 years of experience, Panlabs specializes in the evaluation of wild-type and modified strains, fermentation process development and optimization, and small-scale pilot production. Our expertise covers a wide range of microorganisms, including aerobic and anaerobic bacteria, yeasts, actinomycetes, fungi, and microalgae, with diverse application fields.

Our fermentation team consists of M.S. and Ph.D. holders who combine solid knowledge of microbial fermentation with practical experience. We provide customized process development services to efficiently and accurately meet customer needs, accelerate technology transfer, and achieve commercial-scale production.

Furthermore, Panlabs places great emphasis on the investment and maintenance of fermentation equipment. We have built fermentation tanks of various sizes, offering flexible solutions for different development stages and production scales.

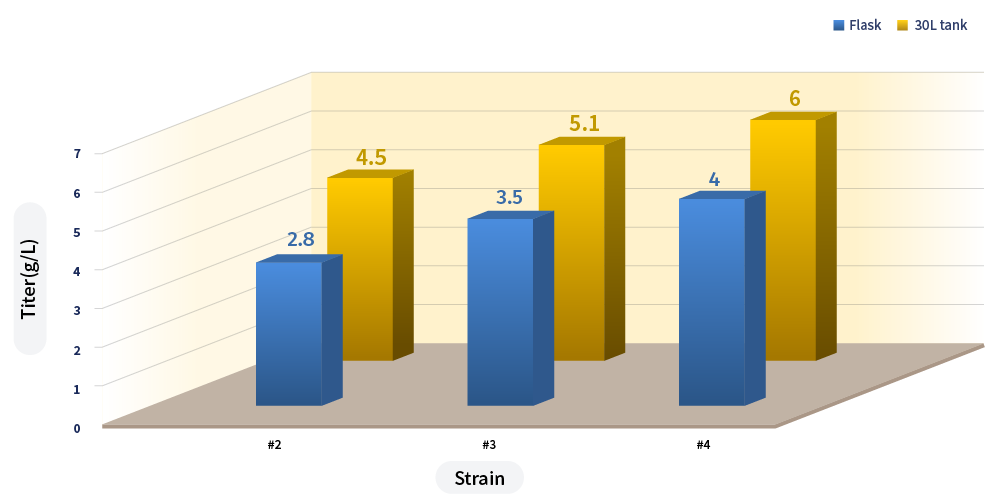

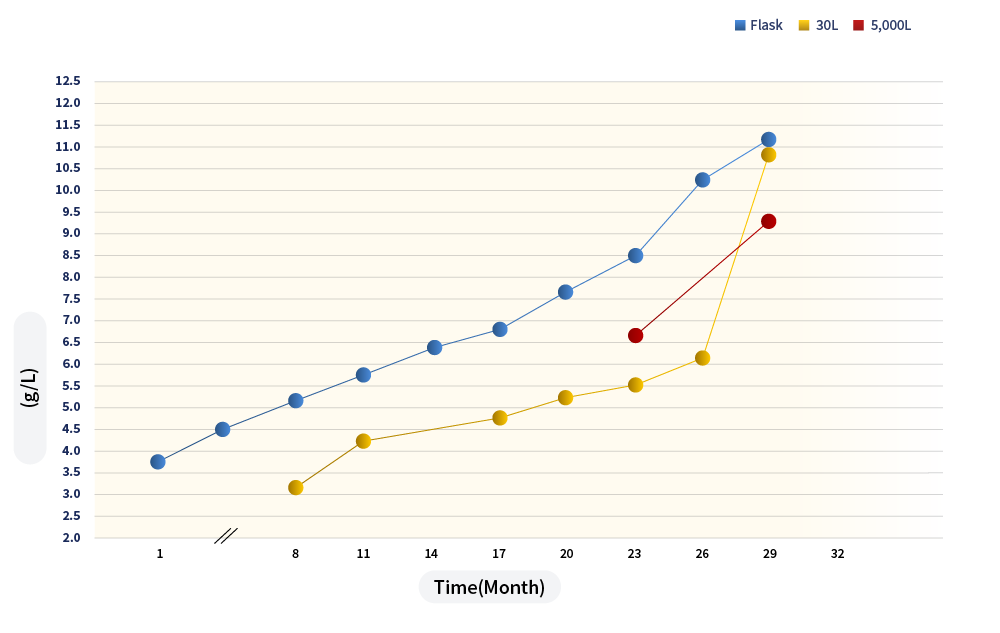

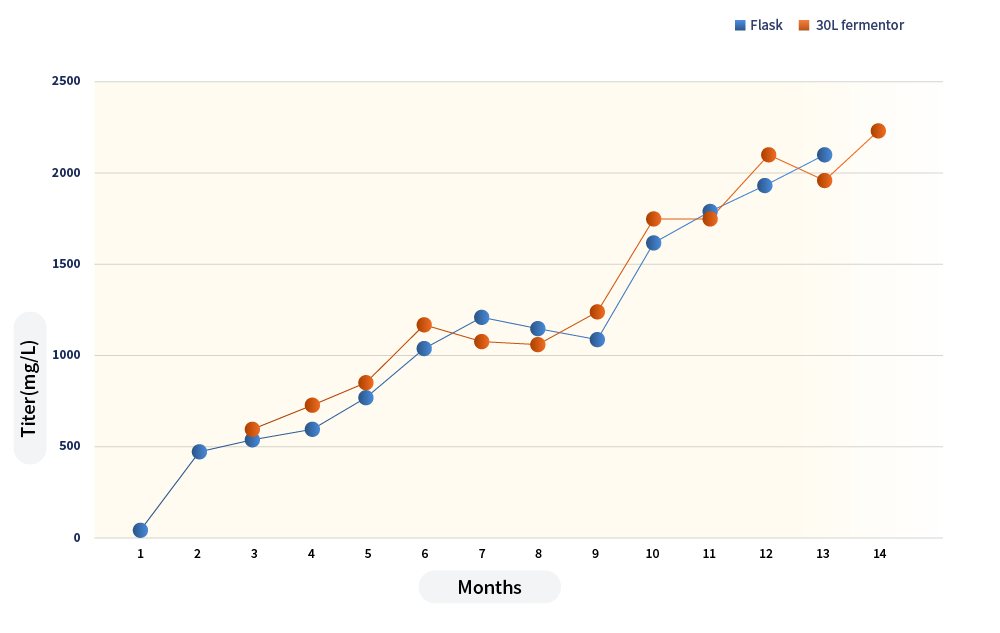

The main purpose of Panlabs’ fermentation R&D is to apply the improved strains in a practical industrial fermentation production. In terms of strain evaluation, we screen improved strains suitable for production in fermenters; in terms of process optimization, we explore the complete fermentation process including pre-culture conditions, media composition, main culture conditions and feeding strategy; in terms of scale up, Panlabs typically use 30L fermentors for validation, whose fermentation conditions can be suitably applied to pilot production. We also work with subcontracted fermentation companies to adjust materials and fermentation conditions to ensure that the plant can produce the desired product directly, quickly and consistently.

In addition, Panlabs is well-known for its excellent technical service, and we are fully committed to assist the customers in their scale-up development. Whether in our partner fermentation plants or in the production plants designated by our customers, we can provide timely explanations and responses in various ways, and offer comprehensive assistance to our customers to facilitate the scale-up production.

Lipopeptide Produced By Fungi